Rivet tiub penuh

As one of professional high quality Full Tubular Rivets manufacturer, you can rest assured to buy Full Tubular Rivets from Notin and we will offer you the best after-sale service and timely delivery.

Full tubular rivets are also called as hollow rivets or tubular rivets, they are a common mechanical fastener, primarily used in applications requiring lightweighting or ventilation. Their structural characteristics are a completely hollow center with heads at each end, achieving connection through plastic deformation. Widely used in electronics, automotive manufacturing, aerospace, and other fields, they are favored for their unique structural design.

What is a hollow rivet?

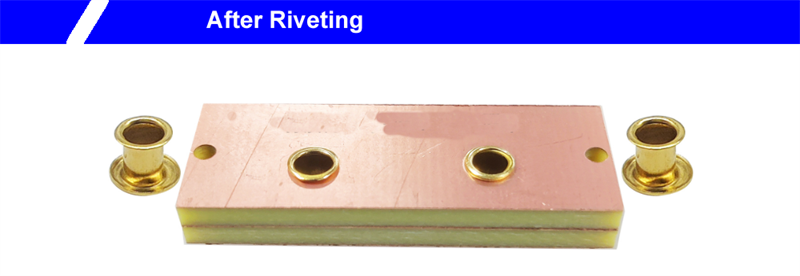

A full tubular rivet consists of a shank and a head. The shank has a through hole in the center, and the head is typically round or oval. During installation, the rivet is inserted through the materials to be joined, and the tail is expanded using a specialized tool to form another head, securing the materials together. Because of the hollow center, full tubular rivets maintain ventilation or fluid conduction after connection, which is their primary difference from solid rivets.

What materials can full tubular rivets be made of? What are the characteristics of different materials?

full tubular rivets are made from a variety of materials, with aluminum alloy, stainless steel, and copper being common.

Aluminum tubular rivets are lightweight and corrosion-resistant, making them suitable for electronic products and lightweight structures. They are the most cost-effective rivets.

Stainless steel tubular rivets are strong and heat-resistant, and are often used in automobiles and industrial equipment. They are more expensive than aluminum hollow rivets.

Brass tubular rivets or copper tubular rivets have good conductivity and are mostly used for electrical connections. Their disadvantage is that they are relatively expensive.

When selecting materials, factors such as the use environment, stress conditions, and cost should be considered.

Installation method of full tubular rivets

Special tools are required to install hollow rivets, such as manual riveting machines or fully automatic assembly machines.

The operation steps are as follows:

(1) Drill a hole in the material to be connected, with the hole diameter slightly larger than the rivet diameter.

(2) Insert the rivet into the hole, ensuring that the head is close to the surface of the material.

(3) Align the rivet hole with the matching punch (the punch is installed on the riveting machine). (4) Shake the riveting machine so that the tail of the rivet is impacted by external force and curls up, forming the same arc as the head, thereby achieving the fastening function.

Advantages of Full Tubular Rivets

(1) Light weight: The hollow structure reduces the amount of material used and is suitable for weight-sensitive applications.

(2) Good air permeability: The through hole in the middle can be used for ventilation or diversion to avoid sealing problems.

(3) Easy installation: Only one-side operation is required, which is suitable for narrow spaces or occasions where the back cannot be accessed.

(4) Low cost: Compared with welding or bolting, the riveting process is simple, saving time and manpower.

Disadvantages of Full Tubular Rivets

(1) Limited strength: The hollow structure leads to weak tensile and shear resistance, which is not suitable for high-load scenarios.

(2) Non-removable: Once installed, the rivet is usually not reusable, and disassembly will damage the connection.

(3) Requirements for material thickness: Materials that are too thin or too thick may affect the riveting effect.

What are the main applications of hollow rivets?

(1) Electronic products: such as computer cases, radiators, etc., taking advantage of their lightweight and air permeability.

(2) Automotive manufacturing: used for non-load-bearing parts such as interior panels and wiring harness fixings.

(3) Aerospace: reduce weight while meeting some ventilation needs.

(4) Furniture assembly: connect metal or plastic parts and simplify the installation process.

Comparison between hollow rivets and other rivets

(1) Compared with solid rivets: full tubular rivets are lighter and breathable, but have lower strength.

(2) Compared with semi-tubular rivets: the tail of semi-tubular rivets is partially hollow, with slightly higher strength, but the ventilation is not as good as full hollow rivets.

(3) Compared with blind rivets: the mandrel of blind rivets remains after installation, while the mandrel of full hollow rivets is completely detached, making the connection neater.

Suggestions for purchasing full tubular rivets

(1) Select rivets of appropriate length according to the thickness of the material to ensure that they can fully expand after installation.

(2) Consider the use environment. For example, corrosion-resistant or high-temperature resistant materials should be selected for humid or high-temperature conditions.

(3) Before purchasing in bulk, you can try it out first to confirm the riveting effect and tool compatibility.

Maintenance and precautions for full tubular rivets

(1) Avoid excessive force during installation to prevent rivet deformation or material damage.

(2) Regularly check the connection parts and replace them in time if they are loose or rusted.

(3) Keep them away from moisture during storage to prevent oxidation of the rivet surface that affects their use.

As a practical connector, full tubular rivets have irreplaceable advantages in specific scenarios. Understanding their characteristics and application methods will help you choose and use them reasonably in actual work, improving work efficiency and connection quality.

- View as

Aluminium Hollow Rivets

Aluminium Hollow Rivet adalah pengikat biasa, mereka digunakan secara meluas dalam banyak bidang kerana berat ringan, rintangan kakisan dan kekonduksian elektrik yang baik. Logam Nuote menghasilkan dan menjual rivet berongga aluminium di China, kami mempunyai pengalaman bekerja lebih dari 10 tahun dalam industri ini.

Baca LagiHantar PertanyaanRivet tiub keluli

Rivet tiub keluli adalah sejenis pengikat logam yang mencapai sambungan melalui ubah bentuk stamping. Mereka terdiri daripada batang tiub berongga dan kepala topi akhir, dan tergolong dalam kategori pengikat berongga dalam bidang kejuruteraan mekanikal. Logam nuote menawarkan jenis rivet tiub keluli di Dongguan, China, selama lebih dari 10 tahun. Selamat datang untuk menghantar reka bentuk anda kepada kami.

Baca LagiHantar PertanyaanRivet Hollow Steel

Logam Nuote mengkhususkan diri dalam pengeluaran rivet berongga keluli. Kami terletak di Dongguan, China. Terdapat dua teknik utama untuk menghasilkan rivet Iron Hollow. Satu adalah menggunakan paip besi, yang sesuai untuk rivet yang lebih panjang. Kelemahannya ialah keperluan kuantiti pesanan minimum agak tinggi. Yang lain adalah menggunakan teknik lukisan dalam. Kami akan memberikan cadangan yang sesuai mengenai teknik yang digunakan berdasarkan keadaan tertentu pelanggan.

Baca LagiHantar PertanyaanRivet tiub keluli tahan karat

Logam Nuote menghasilkan rivet tiub keluli tahan karat di China, rivet tiub keluli tahan karat adalah salah satu penyambung yang biasa digunakan. Oleh kerana reka bentuk berongga, mereka adalah saiz kecil dan ringan, mereka dapat menahan tekanan yang lebih tinggi dan beban tegangan tanpa pecah atau ubah bentuk dan mereka mempunyai ketahanan kakisan yang baik dan rintangan pengoksidaan, itulah sebabnya mereka sesuai digunakan dalam pelbagai persekitaran.

Baca LagiHantar PertanyaanRivet berongga keluli tahan karat

Pengikat memainkan peranan penting dalam industri pembuatan, dan rivet berongga keluli tahan karat, dengan reka bentuk struktur yang unik, digunakan secara meluas di pelbagai industri. Mereka menawarkan rintangan kakisan yang kuat, mengurangkan berat badan, dan peningkatan kekuatan. Ciri -ciri ini membolehkan mereka menahan persekitaran operasi yang lebih keras, memanjangkan hayat produk dan meningkatkan prestasi.

Baca LagiHantar PertanyaanRivet tiub tembaga

Rivet tiub tembaga terutamanya diperbuat daripada tembaga, bahan kemurnian tinggi yang mengandungi sejumlah kecil elemen lain seperti oksigen dan fosforus. Tembaga mempunyai kekonduksian elektrik yang sangat baik dan sering digunakan dalam penyambung elektrik. Reka bentuk struktur rivet tiub membolehkan ia berubah bentuk semasa pemasangan untuk mendapatkan bahan, mewujudkan sambungan yang selamat. Kelembutan tembaga menjadikan rivet paip tembaga kurang terdedah kepada retak semasa pemasangan dan menyediakan sifat pengedap yang sangat baik. Tembaga juga sangat tahan karat dan mengekalkan kestabilan dalam persekitaran lembap, berasid, dan alkali, memperluaskan hayat perkhidmatannya.

Baca LagiHantar Pertanyaan