Kelopak mata

Notin a reputable manufacturer in China, is willing to offer you Eyelets. We promise to provide you with the best after-sale support and prompt delivery.

Eyelets are characterized by quick installation, stable performance, and high reliability. Compared to other fasteners, eyelets are significantly cheaper per unit and have a wide range of applications. They are similar with tubular rivets, but made from different technics and machines.Eyelets are made from deep drawn technics, and tubular rivets are made from tube.

What is an eyelet?

An eyelet primarily consists of a cap and a shank. The cap is typically round or oval, offering a large surface area for easy hammering during installation. The shank is of moderate length and diameter, ensuring the rivet securely connects two or more components. The primary function of this type of eyelet is to connect and secure components, ensuring a secure connection without damaging the material.

What types of eyelets are there?

Based on the material used, they can be categorized as brass eyelets, steel eyelets, stainless steel eyelets, aluminum eyelets, and copper eyelets. Different eyelets have different characteristics depending on their material properties.

Brass eyelets: They offer excellent electrical conductivity and corrosion resistance, making them widely used in various electrical connections and fastening applications.

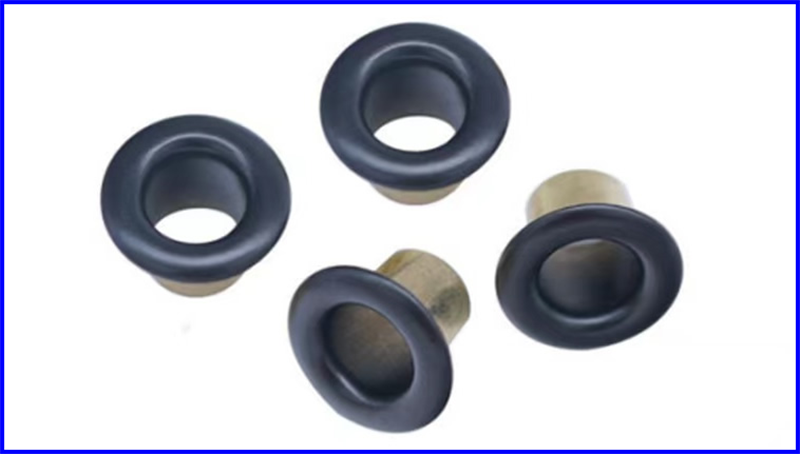

Steel eyelets: steel offers high strength and hardness, and are relatively inexpensive. However, steel has poor corrosion resistance and is prone to rusting, especially in humid environments. Therefore, the application range of iron eyelet rivets is relatively limited.

Stainless steel eyelets: Characterized by their strong corrosion resistance, they are often used for fastening food-grade products. However, due to the material's relatively high hardness, production is challenging, resulting in a relatively high unit price.

Aluminum eyelets: Used for fastening shoelace holes, belt holes, and windbreaker drawstrings, they allow for quick donning and doffing, while enhancing aesthetics.

Copper eyelets: Due to their excellent electrical conductivity, they are often used for connecting and securing electronic products.

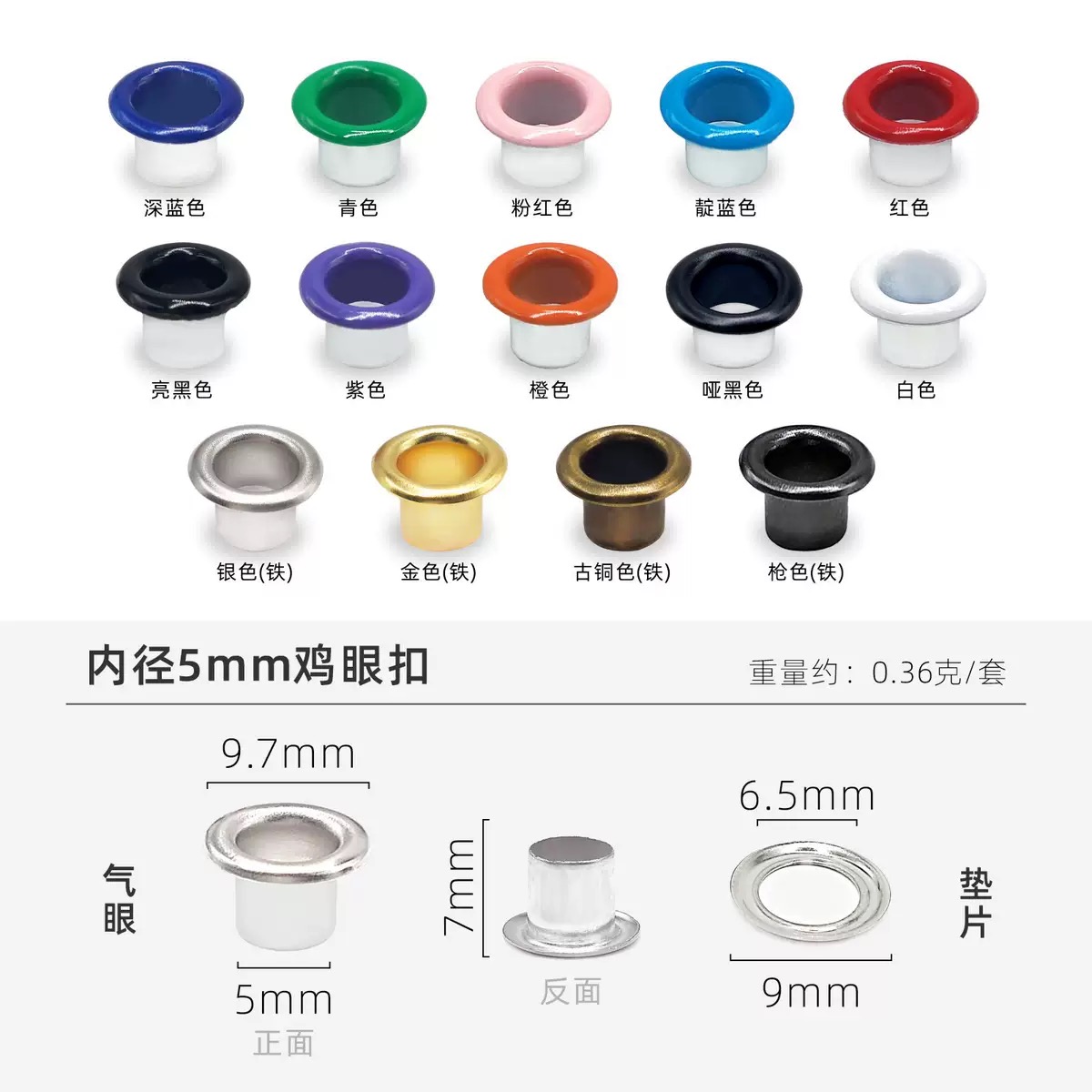

What surface treatments are available for eyelets?

Eyelets are hot-dip galvanized and polished to create a protective layer on the surface that provides antistatic, corrosion-resistant, and anti-allergenic properties. Copper eyelets come in a variety of colors, including white nickel, polished tin, imitation gold, antique bronze, matte nickel, bronze, zinc, and silver.

Some customers also prefer to have the eyelet head powder coating to match their color with the overall design and prevent oxidation.

- View as

Kelopak mata aluminium

Di sini di kilang Dongguan kami, logam Nuote menghasilkan kelopak mata aluminium yang berkualiti. Kami telah memberi tumpuan kepada membuat kelopak aluminium selama bertahun -tahun. Aluminium kami dipilih dengan teliti untuk menjadi ringan dan kuat. Eyelet aluminium ini tidak akan berkarat, dan mereka mengekalkan kemasan mereka yang cerah. Kami menawarkan kelopak mata aluminium dalam pelbagai saiz. Ada yang kecil, yang lain agak besar. Setiap kelopak aluminium diperiksa oleh kakitangan kami. Mereka memeriksa bentuk dan permukaannya. Pelanggan sering memilih kelopak mata aluminium kami. Mereka mendapati mereka boleh dipercayai dan tampan. Kami menyediakan sampel cepat bagi mereka yang ingin mencubanya.

Baca LagiHantar PertanyaanKelopak mata PCB

Kayu PCB adalah cincin logam kecil yang direka untuk dipasang di papan litar. Ia mungkin kelihatan mudah, tetapi ia memainkan peranan penting. Orang menggunakannya untuk membuat lubang yang kuat dan boleh dipercayai dalam PCB. Komponen kecil ini membantu memastikan sambungan tidak rosak semasa pemasangan atau penggunaan. Logam Nuote gembira dapat membantu anda mengetahui lebih lanjut mengenai kelopak mata untuk PCB.

Baca LagiHantar PertanyaanGrommet logam

Kami adalah logam nuote dari Dongguan, China. Kilang kami membuat pelbagai jenis grommet logam untuk kegunaan yang berbeza. Kami telah membuat produk grommet logam selama lebih dari sepuluh tahun. Kami menggunakan logam yang berbeza untuk membuat item grommet logam ini. Tembaga, keluli, dan aluminium adalah bahan biasa. Kami membuat grommet logam dalam semua saiz. Yang kecil untuk kasut, yang besar untuk tarps. Setiap grommet logam diperiksa oleh pekerja kami sebelum pembungkusan. Mereka menguji setiap bahagian untuk memastikan ia berfungsi dengan baik. Ramai pelanggan membeli produk grommet logam kami dengan kerap. Mereka menyukai kualiti dan bekalan yang baik.

Baca LagiHantar PertanyaanEyelet kasut

Kami membuat kelopak mata di kilang kami di Dongguan, China. Eyelet adalah cincin logam kecil, dan anda dapat melihatnya di atas kasut untuk tali. Mereka juga dipanggil sebagai grommets. Kami membuat mereka kuat supaya mereka tidak pecah apabila anda menarik tali anda ketat. Eyelet kasut kami dibuat dari logam yang berbeza, seperti tembaga, aluminium dan keluli tahan karat. Dan mereka boleh dibuat dengan warna yang berbeza untuk memadankan semua jenis kasut.

Baca LagiHantar PertanyaanRivet eyelet

Rivet kelopak mata adalah pengikat kecil tetapi berguna. Ia berbentuk seperti tiub pendek dan sering diperbuat daripada tembaga atau keluli. Apabila dipasang, ekor rivet disapu untuk menyertai bahan -bahan bersama -sama dengan selamat. Banyak syarikat di seluruh dunia menghasilkan komponen yang boleh dipercayai ini. Logam Nuote yang berpangkalan di Dongguan, China, adalah pengilang yang terkenal dengan rivet kelopak mata.

Baca LagiHantar PertanyaanKelopak tirai

Kami menghasilkan pelbagai jenis kelopak tirai di logam Nuote di Dongguan, China. Kelopak mata ini adalah cincin logam yang sering anda lihat di bahagian atas langsir moden. Kami membuat kelopak tirai ini dalam saiz dan kemasan yang berbeza, seperti nikel dan hitam, sesuai dengan pelbagai gaya. Tugas kami adalah untuk memastikan setiap cincin licin dan tahan lama, bersedia untuk digunakan di rumah dan pejabat.

Baca LagiHantar PertanyaanWhat are the main applications for eyelets?

Eyelet rivets are widely used in the construction, automotive, marine, aviation, and electronics industries.

In the construction industry, eyelet rivets are used to connect various metal components, such as steel beams and columns.

In the automotive, marine, and aviation industries, eyelet rivets are used to connect various materials, such as aluminum alloys and titanium alloys.

In the electronics industry, eyelet rivets are used to connect various metal and non-metallic materials, such as metal plates and plastic sheets.

What tools are used to rivet eyelets?

Eyelet rivets can be riveted using either manual or electric riveting pliers. Manual riveting pliers are a common tool and are generally suitable for riveting small eyelets. Electric riveting pliers are suitable for riveting large eyelets and large quantities.

What preparations are required before riveting?

Preparation before riveting includes cleaning the surface of the material being riveted and selecting the appropriate rivet hole diameter. Cleaning the surface of the material being riveted removes surface dirt and grease, ensuring a secure joint. Selecting the appropriate rivet hole diameter can prevent cracking or loosening during riveting.

What precautions should be taken when riveting?

1. The installation position of the eyelet rivet must coincide with the centerline of the rivet hole.

2. The eyelets shank should be perpendicular to the surface of the material being riveted during riveting.

3. The eyelet head must remain horizontally stable.

4. The depth of the eyelet hole should be equal to the sum of the rivet shank length and the length of the eyelet pressure riveting portion.

5. The riveting force should be appropriate, neither too high nor too low, depending on the thickness and properties of the material.

6. After riveting, the eyelets quality should be inspected for signs of broken eyelets or foreign matter.

Conclusion

Eyelet rivets are a versatile rivet fastener that can be widely used to connect various metal sheets and dissimilar materials. Thorough preparation is required before riveting, including selecting the appropriate rivet hole diameter and cleaning the surface of the material being riveted. During riveting, factors such as the riveting force and hole depth should be carefully considered to ensure a high-quality connection.